This post was originally published on Auto Success

People who have served our great nation in the military understand the noun and verb cadence — rhythmical motion or activity. As a former Marine, marching taught me much about how the cadence of things determines outcomes.

Cadence, whether marching, speaking or servicing automobile customers, has the power to transform work processes into something more persistent and assertive. I’m advocating here that a service department can change its frequency of profitability and CSI by transforming its cadence.

It’s unlikely you have the inclination or time to shout out drill sergeant-like work rhythms to your teams. That would be ridiculous anyway, wouldn’t it? The better solution is an automated cadence multiplier that will perform this function quietly, in the background, every minute of the workday, in your repair and maintenance duties, your interactions with customers and your efforts to build their confidence in your services.

Cadence influences workflow cycle time management or how your work phases are done. What breaks that cadence? Think bottlenecks, delays, idle staff and technicians having to scout for parts instead of billing hours in their bays. These cadence disruptions also cause communication gaps that too often leave a customer’s vehicle, all services completed, staged on a lot for which no one notified the advisor or service director.

By reducing cycle times, dealerships can recover this lost time, translating to more billable hours and increased revenue. For example, saving 45 minutes on each service across 10 jobs per day adds 7.5 extra billable hours daily, significantly boosting profitability.

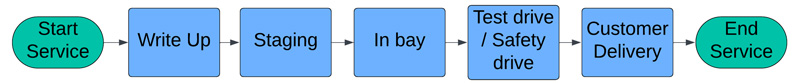

Cycle time management is a remarkable tool for service managers who want to lean out or squeeze more billable hours from their day-to-day service workflow. This chart shows a typical service workflow and the work steps along its flow where time can be lost — and, when known about, recovered. This recovery translates into increased bay utilization, faster step baton transfers and improved CSI when service promises are met.

When you manage cadence in real time, you learn about these time and profit killers in your workflow. Now, you address and eliminate them and train for improvement. There’s no more guesswork, subjectivity or beating your head against the service desk.

When you have a process that tells you where the cadence is in jeopardy and what is causing that misstep, you get tighter in your execution. Quick lane oil services drop from two- to three-hour waits to 90 minutes or less, and customers are happy.

A Capital One study about loyalty notes its importance:

■ 65% of retail business comes from loyal customers.

■ A 5% increase in customer loyalty increases profits considerably.

The bottom line is that how you engage, service and deliver what you promise to customers is critical if you want to capture their ongoing business. Cycle time management alerts you when snags may put delivery time at risk. You can quickly adjust or add resources to meet your promise. When customers can track their service workflow from their phones, you manage expectations and anxiety for the waiter. Dealerships using cycle time management save 45 minutes per service, increase billable hours, reduce wait times by 40% and generate a 35% increase in positive customer reviews. That’s a cadence even a Marine can appreciate.